Unfortunately, humidity and moisture are commons problems families often have in their basements. Whether it be moisture due to a leak in the foundation or humidity because your dryer is venting inside your basement, you must fix it. For insight on how to start and deal with that process, here is some information on how to control moisture and humidity in your basement.

However, before we start it, it’s helpful to quickly explain the difference between humidity and moisture. Moisture refers to the water content when it’s in a liquid phase, while humidity associates with the water content in a gaseous phase. Hopefully, this information helps set a solid foundation regarding the two terms moving forward.

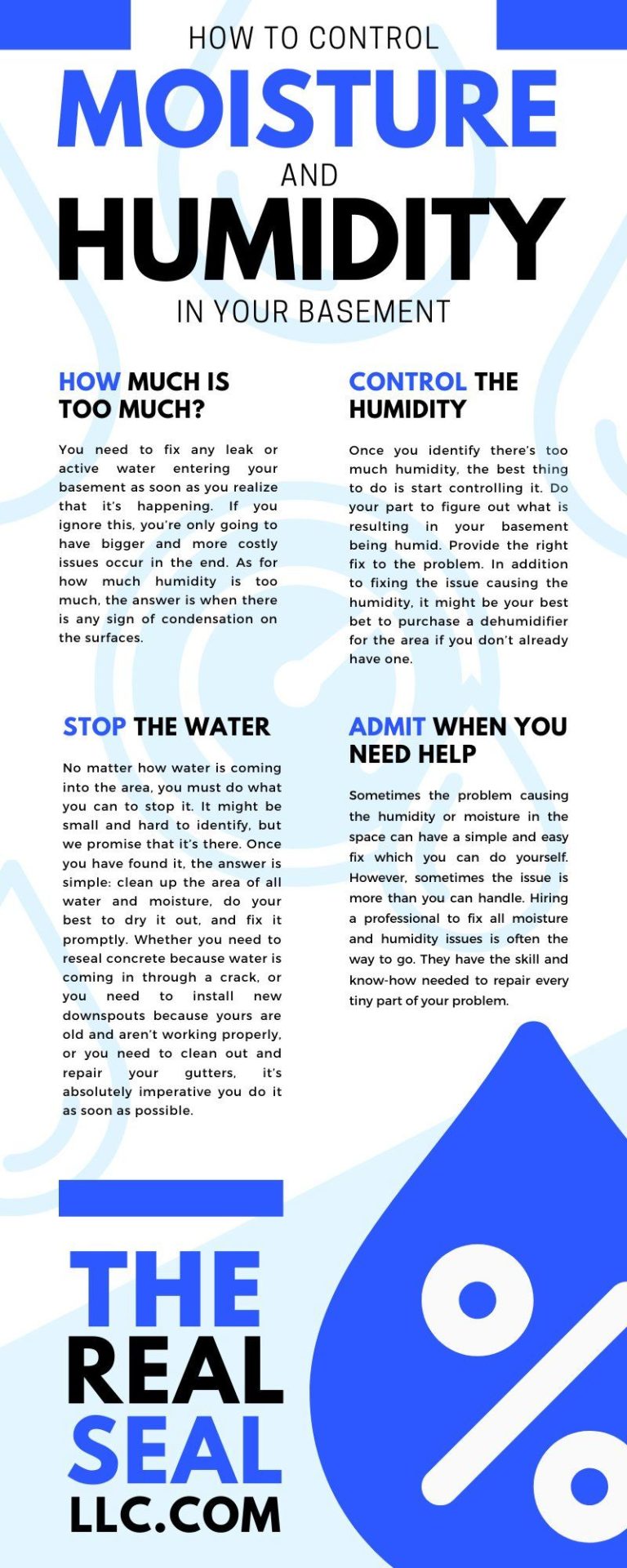

How Much Is Too Much?

This might be a question that you’re asking yourself regarding the condition of your basement, especially if you’ve never dealt with this before. Whether you want to know if a small leak is something you can ignore or if you think that the humidity is at a good level, you must know for sure. Never just assume when it comes to the safety of your home.

Let’s start by getting your first question out of the way. You need to fix any leak or active water entering your basement as soon as you realize that it’s happening. If you ignore this, you’re only going to have bigger and more costly issues occur in the end. As for how much humidity is too much, the answer is when there is any sign of condensation on the surfaces. Condensation is a prominent sign your basement is way too humid.

Control the Humidity

Once you identify there’s too much humidity, the best thing to do is start controlling it. Please note that if you overlook this and don’t deal with it, it can lead directly to moisture and cause more issues for your home. However, to control it you need to understand what exactly is causing it. Aside from leaks and puddles—which we will take about later—humidity can be caused by many other factors. Here are a few examples:

The soil around your home has become oversaturated and is making its way into the basement through the concrete.

One of your appliances isn’t venting to the outside of your home, but rather into your basement.

Water is present underneath the foundation of your home.

Humid air has access into the area.

Do your part to figure out which cause is resulting in your basement being humid. Provide the right fix to the problem. In addition to fixing the issue causing the humidity, it might be your best bet to purchase a dehumidifier for the area if you don’t already have one. Combine the dehumidifier with keeping all windows shut, as well as turning up your heat. Before you know it, your space will be free of humidity.

Stop the Water

No matter how much water is coming into the area, you must do what you can to stop it. This might not be the easiest job, considering it might be difficult to locate the source of the problem. However, if moisture is present, there is a problem somewhere. It might be small and hard to identify, but we promise that it’s there. Once you have found it, the answer is simple: clean up the area of all water and moisture, do your best to dry it out, and fix it promptly.

Whether you need to reseal concrete because water is coming in through a crack, or you need to install new downspouts because yours are old and aren’t working properly, or you need to clean out and repair your gutters, it’s absolutely imperative you do it as soon as possible. Ignoring problems such as these will only cause more severe issues going forward—not only for your basement but your entire home. Water entering your home and the subsequent moisture buildup is dangerous and unsafe. It’ll cause mold and mildew to grow, which will endanger the structure and safety of your home.

Admit When You Need Help

There is no harm in asking for help! Sometimes the problem causing the humidity or moisture in the space can have a simple and easy fix which you can do yourself. However, sometimes the issue is more than you can handle. Whether you can’t figure out what the problem is and why these issues are occurring, or you found the problem but just can’t fix it—that’s okay.

Hiring a professional to fix all moisture and humidity issues is often the way to go. They have the skill and know-how needed to repair every tiny part of your problem. If you can locate the problem but not fix it, or can only fix the problem halfway, professionals are there to assist you. They’ll repair the issue skillfully and efficiently. Choosing a company that deals with waterproofing will allow you to get whatever assistance you need for your basement.

Reading this information regarding how to control moisture and humidity in your basement will help you be a better homeowner. In this article, not only did we share how to handle the problems regarding humidity and moisture, but we showed you also how damaging it can be if you ignore it. Being a responsible homeowner is the way to go. You’ll be safe and, best of all, so will your home!

Read more about – Why Water Leaks Could Cause Pests Problems?

Speaking of being a responsible homeowner, if you’re looking for basement waterproofing in Chicago—you’ve come to the right place! Here at The Real Seal LLC, we want to do our part in keeping your home safe and your basement dry. Hiring our team to do all things waterproofing, as well as deal with humidity and moisture, is one of the best decisions you could make. Take a look at our website today to see all the services we have available and give us a call. We look forward to speaking with you about how we can do our part in making your basement better than ever!

One Response

[…] Especially consider humidity and moisture as these are common problems families often have in their basements. Whether it be moisture due to a leak in the foundation or humidity because your dryer is venting inside your basement, you must fix it. Once you identify too much humidity, the best thing to do is to control moisture and humidity. […]