Cracked concrete is more than just a cosmetic issue. A cracked sidewalk is also a trip hazard. Fortunately, there are concrete crack repair methods to correct the problem. After the repair is complete, you might not even know the crack existed. In this article, we’ll review why concrete slabs become uneven, how cracks in slabs are repaired, how to help prevent problems with concrete slabs, and more.

Why Do Concrete Slabs Like Sidewalks and Driveways Become Uneven?

Any concrete slab can experience problems, regardless of if it is a sidewalk or a larger slab, such as a driveway. Concrete is a very common building material that is heavy and does not give under pressure. That is why, when problems occur, you often see uneven areas and cracking. The following are some of the most common reasons why it takes place:

- Drainage: Water is one of the biggest problems for concrete slabs, and it can affect the slab differently. This is especially true when the water doesn’t drain from the area properly, as it can cause the underlying soil to erode. As the soil washes from under the slab, it leaves behind voids, and the concrete may begin to sink. This causes uneven areas at the edge of the slab, or the slab may crack under its own weight.

- Soil Conditions: If the soil cannot handle the slab’s weight or if it was not properly prepared before the slab was poured, the slab could sink, leading to uneven concrete and cracking.

- Nearby Trees: When tree roots grow, they can push against the underside of the slab, and the pressure will eventually cause the slab to lift and crack. At times, this type of cracking may be a spiderweb crack, which may not be able to be repaired. The concrete must be removed and replaced if the cracks can’t be repaired.

- Weather: When a storm drops an excessive amount of rain quickly, it can overwhelm the drainage system and cause the soil under the slab to erode.

- Freeze/Thaw Cycles: As the ground freezes, it will lift the concrete slab. When the ground thaws, the slab will drop. This creates movement and can eventually cause cracking and unevenness. Concrete itself is also subject to changes during freeze and thaw cycles.

How Is Concrete Crack Repair Done?

There are different methods for concrete crack repair, but the industry standard today is polyjacking. It uses rapidly expanding polyurethane foam to lift the slab into place. As it does so, the cracks will close to a large extent. Here’s the general repair process:

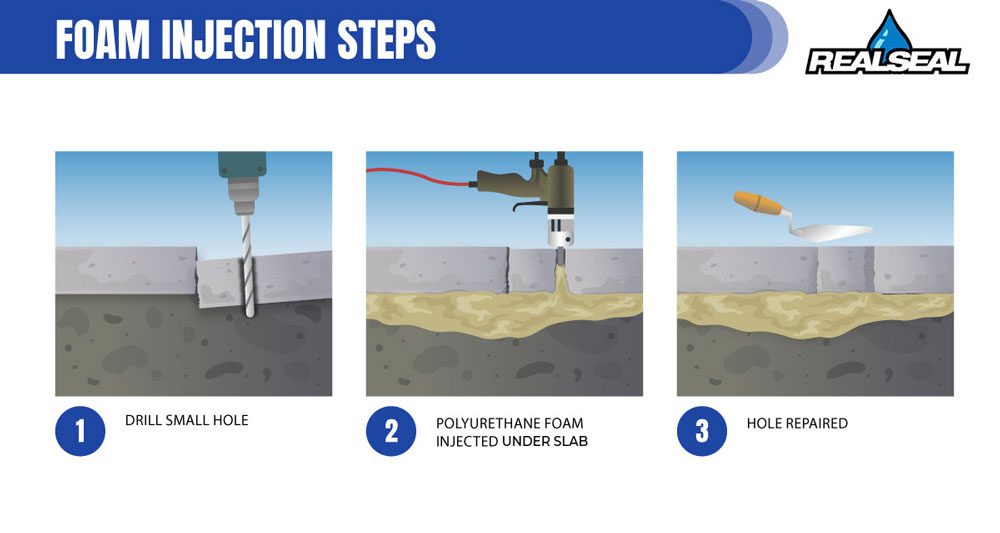

- Drilling Holes: The first step in the polyjacking process is to drill holes in the concrete. The holes are approximately the size of a dime. After the holes are drilled, injector ports are pushed into the holes to allow our polyjacking equipment to connect.

- Injecting Polyurethane Foam: Polyurethane foam is injected through the ports into the voids under the slab. As the foam quickly expands, it compacts the soil under the slab and simultaneously pushes up on the slab to lift it.

- Filling Holes: A special compound fills the holes after removing the ports. The compound is made to closely match the color of the slab.

- Begin Use: The job is complete within 15 minutes after the polyurethane foam is put in place. The slab can be used normally at that point.

Concrete Crack Repair Before and After

Does Every Cracked Concrete Slab Respond Well To Polyurethane Foam Injection?

Most cracked slabs will respond well to polyjacking. Certain types of cracks are not able to be repaired. When those cracks exist, the concrete must be removed and replaced.

Spiderweb Cracks often occur due to nearby tree roots growing under the slab. Concrete heaving can also lead to spiderweb cracks. Since the concrete is significantly damaged, it must be removed and replaced.

Another issue that can not be fixed with polyjacking is when there are low spots in the center of the slab. This issue occurred when the slab was poured, and it can not be fixed in this way, as the center of the slab can not be raised independently of the edges.

Additionally, concrete can “sag” over time, especially with weight above. You may have noticed how a neighbor’s concrete driveway has 2 sunken tracks where cars drive over it. These happen over time, and cannot be undone with Polyjacking.

Can I Use Foam To Repair A Cracked Concrete Slab On My Own?

Most DIY concrete slab repairs are little more than window dressing, and don’t address the underlying issues. Even if you could inject polyurethane foam under the slab, doing so could cause additional problems. Polyjacking is a process that only professionals should implement. The Real Seal has the specialized equipment and the trained personnel to care for this job and to get it done right. The slab will be raised to close the cracks without raising it too far and causing more issues. Plus, after we leave, the slab is ready for use and as good as new.

Is Polyjacking Better Than Mudjacking?

The Real Seal uses polyjacking to raise sunken concrete slabs and address the cracks and uneven areas. It is the industry standard and should be the only way your cracked concrete is ever repaired. There are some companies out there that still use mudjacking to accomplish concrete crack repair. However, polyjacking is the go-to standard today for a reason. Here’s why:

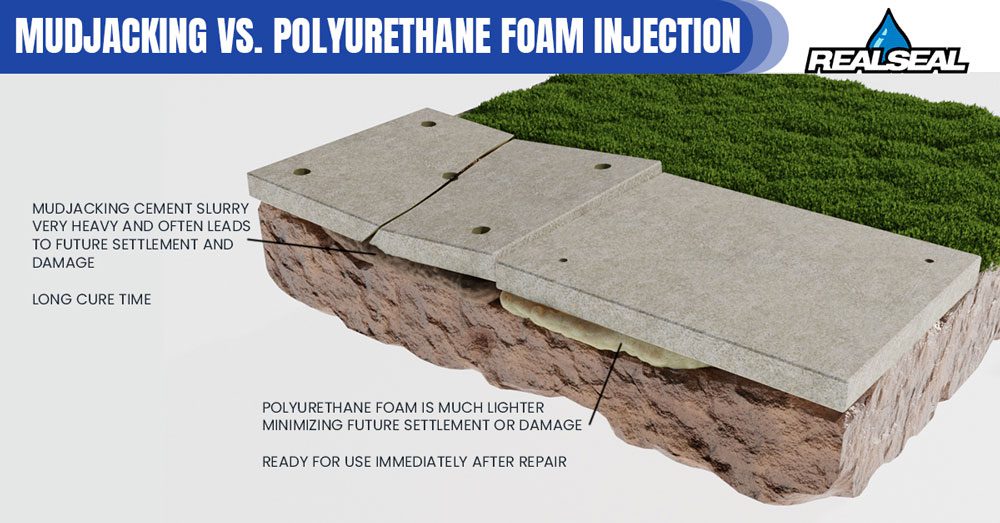

Mudjacking is an old-school technique that pumps a heavy cement slurry through large holes in the concrete to raise the slab into place. On the surface, it sounds a lot like polyjacking, but some significant differences make polyjacking the superior choice.

- Appearance: Polyjacking uses small holes through the concrete, but mudjacking uses 2″ holes. Therefore, the repair is more visible.

- Material: Polyjacking uses environmentally friendly polyurethane foam that will not break down over time. Mudjacking uses a mixture of cement, mud, and water that can eventually erode.

- Weight: The mudjacking slurry is heavy and may eventually compress the soil beneath the slab, allowing it to settle again. Polyurethane foam is extremely lightweight.

How to Help Prevent Concrete Slabs from Cracking and Becoming Uneven

You can prevent concrete slabs from settling and cracking in several ways. Some options must be done from the start; others can be done later.

If the concrete has not yet been put in place, you must ensure that the soil under the slab is properly compacted. This is one of the most common reasons why a concrete slab cracks. If you don’t compact the soil in advance, the slab’s weight will compact the soil and then start to sink.

Make sure you have the cement mixture correct. If there is too much or too little water in the mixture, the concrete will not dry properly and cracks are more likely to form.

If the slab is already in place, ensure adequate drainage to keep water from pooling and washing away the soil under the slab.

If trees are nearby, keep a close eye on the roots and don’t let them grow under the slab because they could push up on it and cause it to crack.

If you have any questions about concrete cracks or uneven areas in your sidewalks, patios, or driveways, call The Real Seal. One of our industry experts will get back to you and make sure the problem is resolved.